Customized process-automation software for a car wash

LiteBreeze built a custom product that automates the daily processes of car washing shops. This user-friendly system assures the least manual involvement during the whole car washing process.

The minimalist user interface and streamlined flow of events make this system easy to follow even for first-time users.

It makes use of Raspberry Pi and a PLC (Programmable Logic Controller) as the main processing unit for the entire operation that integrates the kiosk terminal and the car washing machine.

The software is developed in Go, an open-source programming language developed by Google, which guarantees robust performance. It is a standalone unit that can work both online and offline.

Key Features

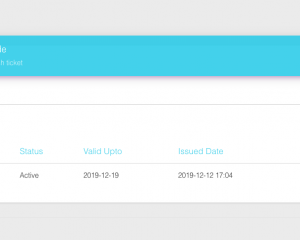

Automated ticketing

Customers can contact the staff to choose their preferred wash program and generate a custom ticket. Each generated ticket is unique and could be used to start the washing process.

If the ticket is expired the screen will display an error message.

PLC integration

The kiosk is run with the help of a pre-programmed Raspberry Pi unit, bridged to a PLC (Programmable Logic Controller).

The PLC is what connects the UI to the mechanical part of the car wash. Once the user inserts the generated ticket into the kiosk, the PLC tells the car wash to run the preferred wash program.

Admin backend

Admin users can create, update and delete staff users from this module.The system will generate a unique ID for the staff users, they have to use the unique ID for generating the tickets.

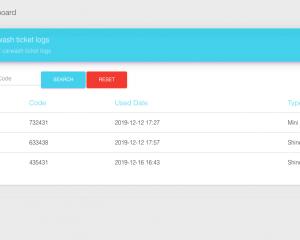

Log lists

The ticket logs/history are saved and could be accessed by staff and admin users. They can filter the wash logs list by entering either the wash ticket code or date.

Minimal UI

The minimalistic user interface design makes it easy on the eyes. The buttons, instructions, and tabs are well-defined and even new users could get hold of the process in a gist. It is easy to operate from the car.

Technical Information

The application is developed in Golang, with the Beego framework. A customized Raspberry Pi module acts as the internal computer/processor of the terminal.

The automation chain is powered by Snap7. It acts as a low cost-high performance computing device on which we preprogram the terminal’s UI and its functionalities. Snap7 scales easily and is designed to transfer large amounts of hi-speed data.

A PLC is implemented as the bridge between the UI and the mechanical unit of the car wash.

Next priorities

Customers/end-users will be able to interact with the kiosk interface where they will be able to choose their preferred wash program and generate a custom ticket.

The kiosk is integrated with a printer which will, in turn, dispatch each ticket generated via customer interaction, without any external prompt.

This will totally eliminate the need for staff interaction during ticket generation.

- Joachim Hylén